Fabrication Options

Splices, edge reinforcements, tracking & guiding devices

Metallic Splices

Alligator Splice

Alligator Splice

Taconic offers #1A galvanized or #1A stainless steel alligator splices. These splices are the most durable and easiest to use. Belts utilizing alligator or clipper splices can be installed without taking machinery apart. A coverflap can be added to reduce heat transfer to your material.

Clipper Splice

Clipper Splice

Taconic offers OTSS and #25 stainless steel clipper splices. These splices are the most durable and easiest to use. Belts utilizing clipper and alligator splices can be installed without taking machinery apart. A coverflap can be added to reduce heat transfer to your material.

Non-Metallic Splices

Peek Splice

Peek Splice

Peek splices are an ideal choice when metallic splices cannot be used. Either a peek or smart loop splice should be chosen when maximum airflow is desired. Smart Loop Splice

Smart Loop Splice

Smart loop splices are an ideal choice when metallic splices cannot be used. Either a peek or smart loop splice should be chosen when maximum airflow is desired.

Self Loop Splice Self loop splices utilize a 1.5" foldover onto itself and can be heat sealed or sewn. Self loop splices offer maximum airflow and are recommended for narrow belts.

Self Loop Splice Self loop splices utilize a 1.5" foldover onto itself and can be heat sealed or sewn. Self loop splices offer maximum airflow and are recommended for narrow belts.

Fabric Notched Splice

Fabric Notched Splice

A fabric notched splice is similar to the alligator splice but completely eliminates the metal clip. It uses a PTFE Kevlar® material with a special pin for joining.

Endless Splices

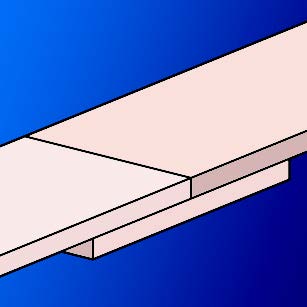

Butt Splice

The ends of the belt are butted together and joined by sealing a strip of reinforcing fabric under the butted ends. Butt splices provide the smoothest belt surface at the joint and eliminate the step-down surface which is characteristic of the overlap splice.

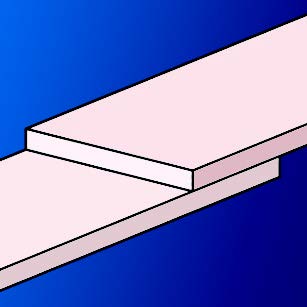

Overlap Splice

Overlap Splice

This is the standard splice for most applications. Overlap splices, normally cut and overlapped on a 90, 60 or 45 degree angle, are also commonly used since they are more flexible when running on smaller diameter rollers. Standard overlap splices are 1".

Scarfed Splice

Scarfed Splice

To prepare a scarfed splice, the ends of the belt are "scarfed", or sanded down and joined, eliminating the double thickness at the splice which is characteristic of the overlap splice. A scarfed splice also eliminates the need for a heat-sealed reinforcement at the splice characteristic of the butt splice.

Edge Reinforcements

Taconic belts can be supplied with strips of heat-sealed film or fabric on one or both edges of the belt. This reinforcement serves a dual purpose: it reduces fraying of belt edges which rub on guide rollers and it also provides the strongest possible anchor for guiding pins, snaps and grommets.

PTFE Film Edge, Heat-Sealed

PTFE Film Edge, Heat-Sealed

PTFE film edges are heat-sealed to the top and bottom of the edges of the belt for a 1/2" or 1" (standard) surface. The PTFE film is available in 3 mil black or clear and 10 mil tan (1" surface only).

Fabric Edge, Heat-Sealed

Fabric Edge, Heat-Sealed

Six mil fabric is heat-sealed to the top and bottom of the edges of the belt for a 1" (standard) or 2" surface. Fabric edges are available either tan or black.

Fabric Edge, Sewn & Sealed

Fabric Edge, Sewn & Sealed

For extra reinforcement, our 6 mil heat-sealed fabric edge can also be sewn if desired. This reinforcement is commonly used on open mesh belting.

Tracking & Guiding Devices

Taconic offers a variety of options to guide belts on your machine. These devices can be placed on one or both edges of your belts.

Snaps

Snaps

Nickel snaps are available in .37" diameter and .12" deep.

Grommets

Grommets

Nickel plated brass grommets are offered in three sizes:

#00: 0.1875 I.D. x 0.5625 O.D.

#1: 0.3125 I.D. x 0.6875 O.D.

#2: 0.375 I.D. x 0.875 O.D.

![]() Silicone Rubber Guide

Silicone Rubber Guide

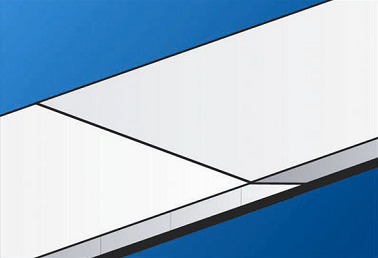

A silicone rubber guide is also available to assist with accurate tracking. Two-Ply Belts

Two-Ply Belts

Two-ply belts are constructed of two plies of PTFE coated fiberglass laminated together with staggered splices. This provides a smooth, continuous thickness along the entire belt length which guarantees a uniform seal in packaging and heat-sealing applications. The belts are typically available in widths of 1/3" to 3".