Hydrogen Fuel Cell Materials

PEM fuel cell production materials and gasketing fabrics / tapes for COPV manufacturing

Hydrogen Fuel Cell Materials

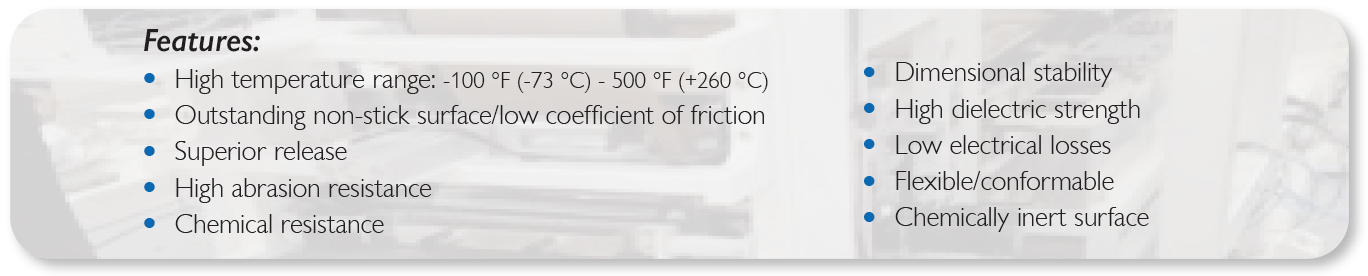

Taconic’s PTFE Coated Fiberglass Fabrics for Hydrogen Fuel Cell component production offer a dimensionally

stable coating carrier during the anode and cathode roll to roll coating process.

Taconic’s PTFE coated fabrics provide clean release during transfer/decal lamination onto the PEM (Polymer Electrolyte

Membrane aka Proton Exchange Membrane) to make the MEA (Membrane Electrode Assembly).

As Fuel Cells continue to push into the renewable energy space, researchers and manufacturers alike have turned

to Taconic’s PTFE coated fabric materials to reduce costs, improve production processes, and increase end-product

reliability/lifespan.

PEM Fuel Cell Production: - Benefits of PTFE coated fabrics for roll-to-roll coating

- Mechanical strength during casting roll-to-roll processing

- Reduced surface roughness

- Release properties of film surface

- Cost savings

Gasketing fabrics and tapes for COPV manufacturing and parts:

- COPV dome protection parts

- Release fabrics for composite manufacturing molds

- High heat resistance

- Custom C.N.C cut profiles

Product Highlights

Fabrics and Films for PEM Fuel Cell Coatings/Decal Lamination:

7030-1 & 7030-1S: Single use fabric with smooth surface. Ideal when microinch roughness is imporant and where castings require clean and easy release. Micropinhole free.

7069: 6 mil PTFE coated fabric which exhibits exceptional release properties, heat resistance and chemical resistance. Ideal where heat transfer is desired.

Film and foil versions available: PTFE skived film, coated aluminum foils, coated PI films, and other coated films available

Tapes for COPV manufacturing and parts:

6085-03: Single use fabric with smooth surface. Ideal when microinch roughness is imporant and where castings require clean and easy release. Micropinhole free.

6085-06: 6 mil PTFE coated fabric which exhibits exceptional release properties, heat resistance and chemical resistance. Ideal where heat transfer is desired.

6115-05: Adhesive coated PTFE skived film. Other thicknesses available.

| Part Number |

Overall |

Coated Weight | Tensile Strength Warp/Fill (lbs/inch) | Tear Strength Warp/Fill (lbf) | Dielectric Strength (volts) | Operating Temp. Min/Max (°F) |

|---|---|---|---|---|---|---|

| 7030-1 | 0.0033 | 0.33 | 90 / 55 | 3.4 / 2.7 | 3500 | -100 / 500 |

| 7030-1S | 0.0033 | 0.33 | 90 / 55 | 3.4 / 2.2 | 5000 | -100 / 500 |

| 7069 | 0.0060 | 0.59 | 175 / 160 | 5.0 / 4.0 | 6000 | -100 / 500 |

| 6085-03 | 0.005 | - | - | - | - | -100 / 500 |

| 6085-06 | 0.008 | - | - | - | - | -100 / 500 |

| 6115-05 | 0.007 | - | - | - | - | -100 / 500 |