Tacsil F20BP FPC Carrier Tape

A cost effective FPC carrier tape solution for FPC assembly

Tacsil F20BP offers a cost effective solution to FPC assembly over conventional methods. Polyimide tapes, resin coated plates and double sided tapes can increase costs, lower productivity, contaminate and/or damage flexible circuitry, reduce print accuracy and create environmental issues. With TacSil F20BP, FPC assembly just got easier. TacSil is available in sheet or roll form.

Technical Data

Benefits

• Performs more than 500 cycles in SMT processing

• Excellent dimensional stability at 500 °F

• Precise surface mounting

• No adhesive residue

• Superior surface flatness allows whole area fixation

• Excellent die-cut properties

• Provides flexibility to carrier designers

• Durable anti-static surface

Main Applications

• SMT Processing of flexible PCB's

• SMT processing of thin rigid PCB's

• Carrier of LCD assemblies

• Flip chip mounting process

• Various temporary fixing applications

| TacSil | Thickness (mil) | 180-deg peel adhesion (oz/in.) |

Operating Temp. Max °F | Shelf Life | |

|---|---|---|---|---|---|

| Active Side |

Mounting Side | ||||

| F20BP | 0.0050 | 1.1 +/- 0.2 | 25 minimum | 500 |

1 year from D.O.M. |

| ASTM D4969 | ASTM D3330 | ||||

*Available in sheet or roll form.

How to apply TacSil in SMT processing

If you use Durostone or aluminum boards, you will need to pre-age the Durostone or aluminum board itself before applying Tacsil in order to remove entrapped air within the board. Other material boards to not require pre-aging.

How to pre-age:

- Pre-age at 500 °F for more than 3 minutes or pass through SMT reflow chamber for one cycle.

- For Durostone boards, attach Tacsil to the Durostone 2 hours after pre-aging. For aluminum boards, attach Tacsil before the aluminum board cools below 100 °F.

- Pre-age Durostone or aluminum carrier

- Clean surface of carrier boards with alcohol

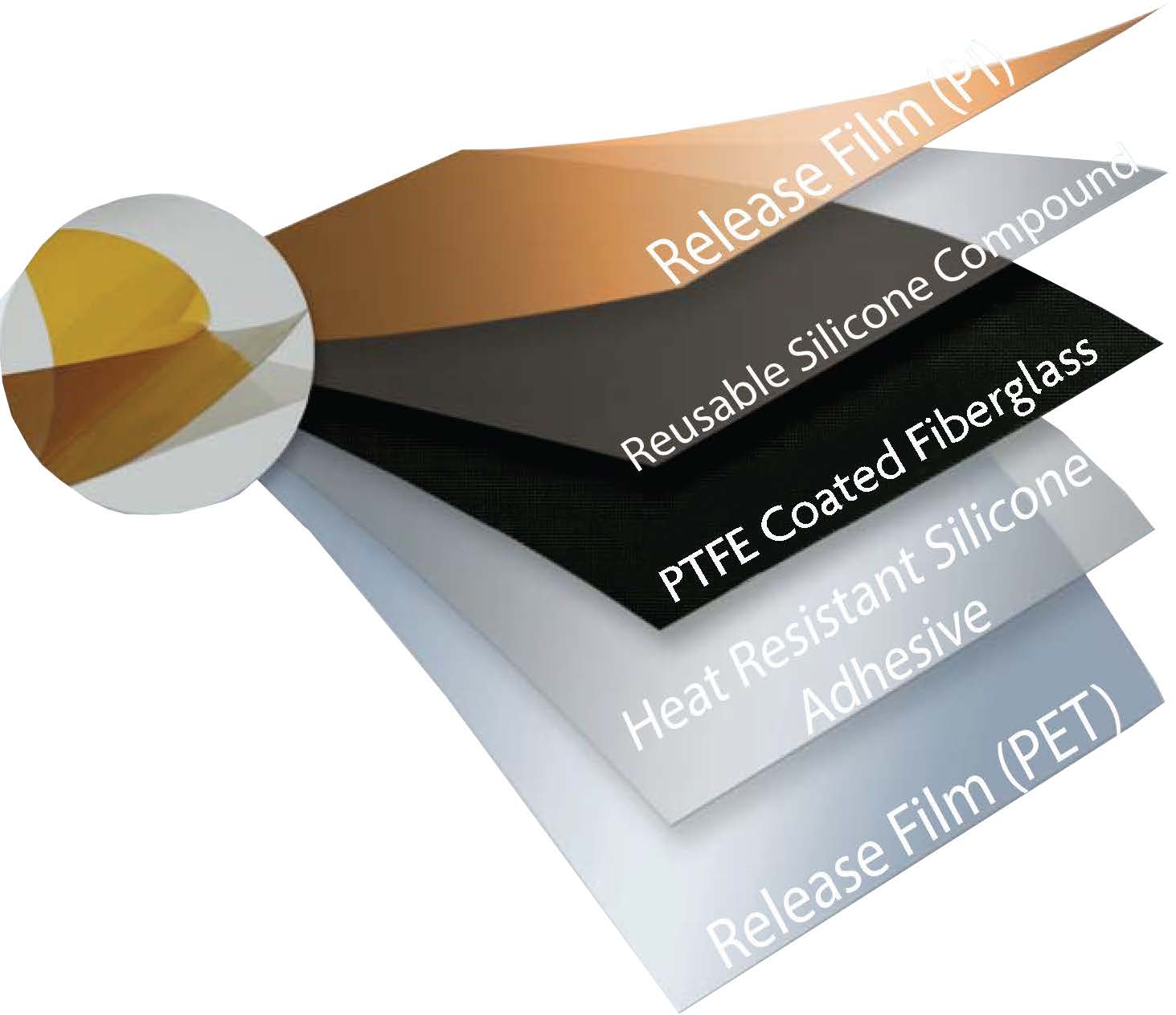

- Carefully remove release liner from adhesive side (clear liner)

- Attach adhesive side of Tacsil to board

- Carefully remove release liner from silicone side (amber PI film liner)

- Put FPC on the silicone surface

Cleaning:

Proper cleaning can extend the life of TacSil; cleaning the active surface is recommended when the tack is no longer high enough to hold the FPCB. Surface contamination can be removed using the available cleaning roller (recommended) or with a soft cloth moistened with Ethanol. Ketones such as Acetone and solvents such as toluene and xylene are not recommended for cleaning.

| Cleaning Product | Lot # | Item Description |

Operating Temp. Max °F | |

|---|---|---|---|---|

| Handle | 20150813 |

Cleaning roller handle | M |

|

| Roller Refill | Perforated adhesive cleaning roller sheet | 80 mm x 20 m | ||

Storage Consitions:

- Keep products away from direct UV exposure, oils and any other contaminants

- Store at 73 °F +/- 4 °F, 50 +/- 2% RH in original packaging.