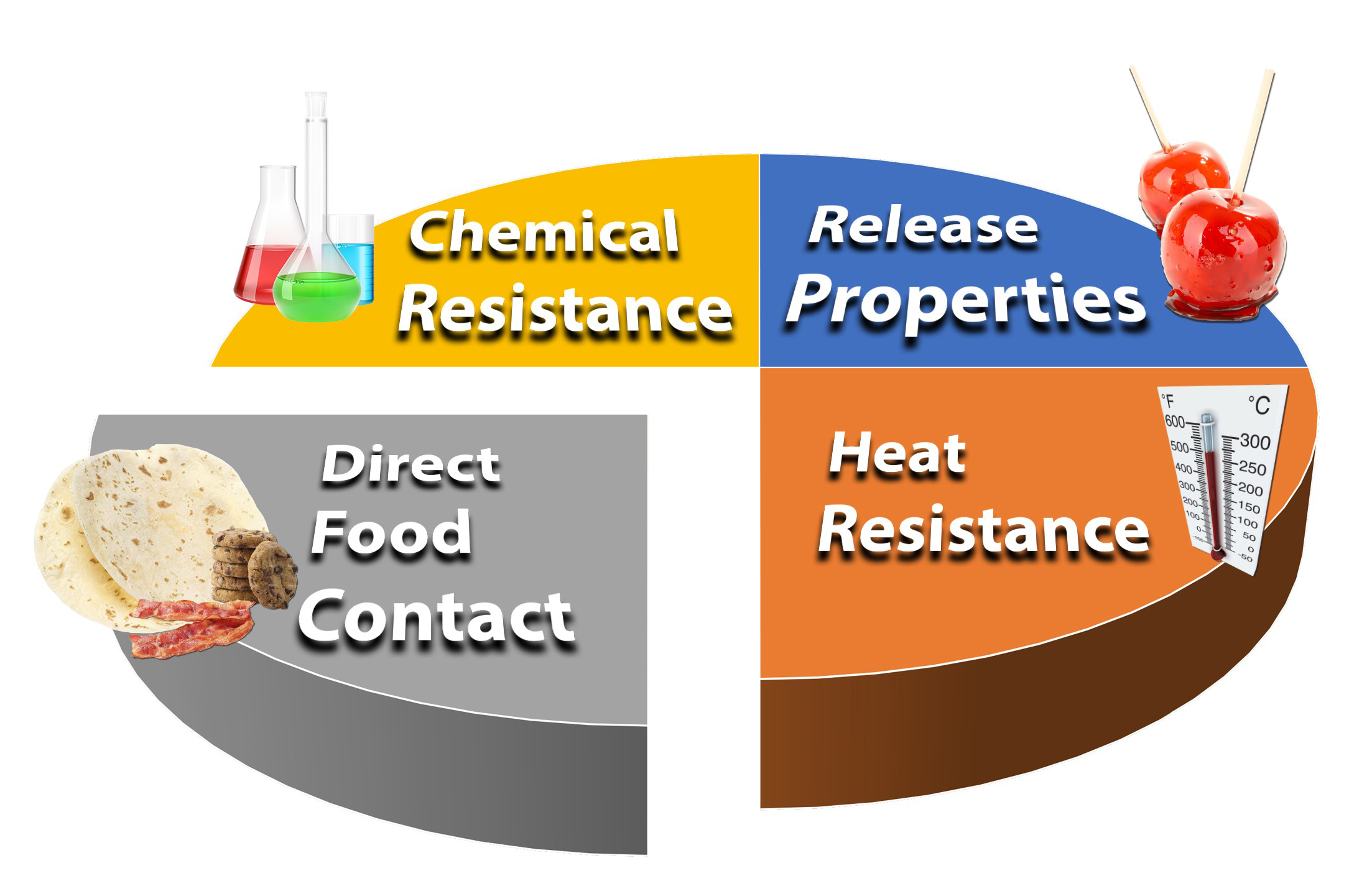

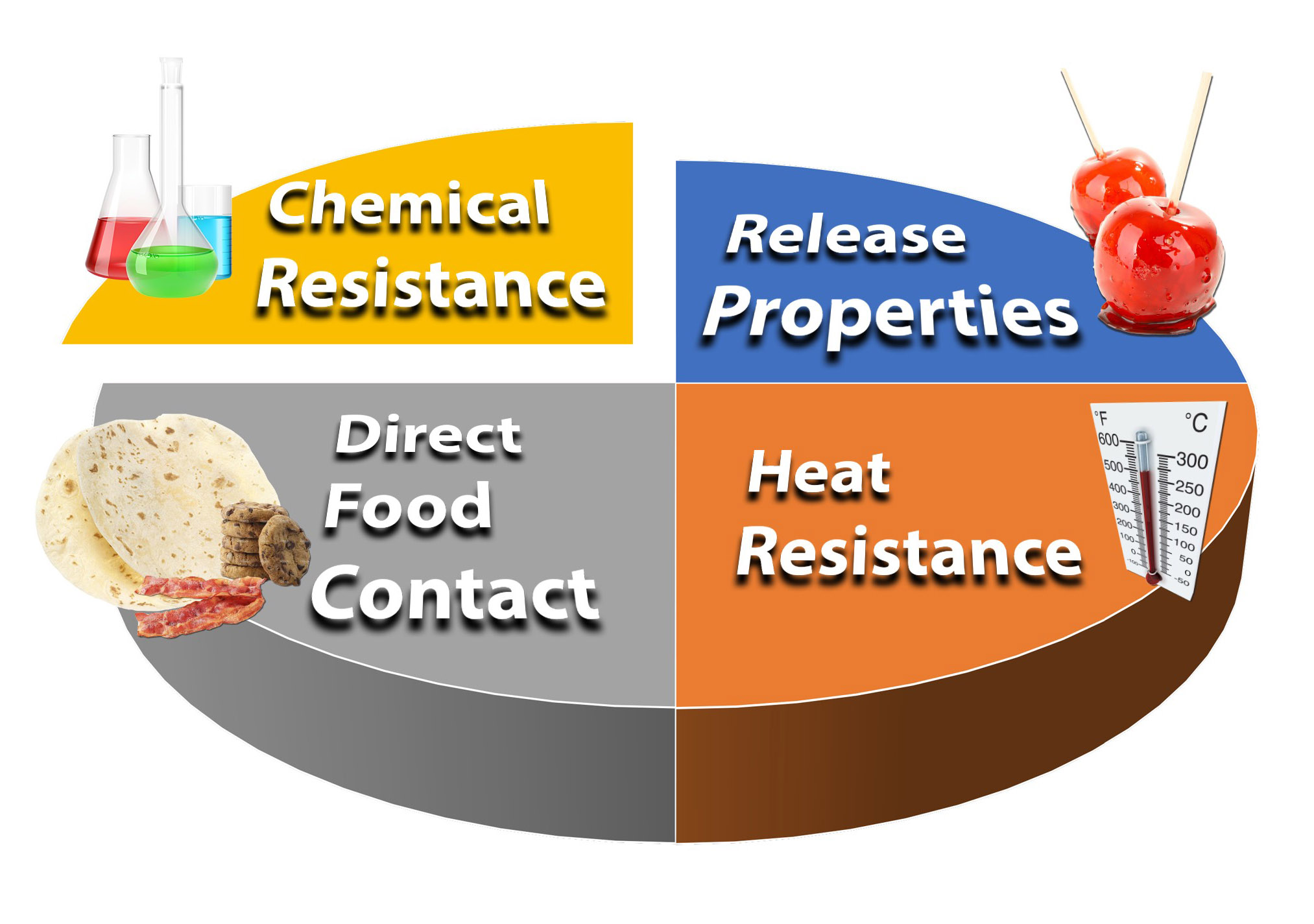

What Makes PTFE Coated Fiberglass Unique?

Heat Resistance

High temperatures can breakdown most fabrics, tapes, and belts. Taconic’s heat resistant materials allow for fewer changeovers, higher line speeds, longer life, and an overall lower cost of production.

• PVC Window Welding

• Polybag Manufacturing

• Cooking Sheets (baking)

• Heat Sealing & Flexible Packaging

• Cooking/Grilling Belts (meats, eggs, pancakes, and more)

Release Properties

At Taconic we like to say “nothing sticks on our watch” - and that’s all thanks to the superior release properties of our PTFE coated materials.

• Cooking/Grilling

• Heat Sealing and Flexible Packaging

• Baking

• Roller Wrapping

• PVC Window Welding

• Chute Liners

• Wear Strips

• Polybag Manufacturing

Direct Food Contact

At Taconic, we respect the integrity of your food production processes. For that reason, we ensure that all our food grade PTFE coated glass fabrics and conveyor belts fully comply with relevant FDA & EU regulations.

• Industrial meat cooking lines

• Tortilla and pizza production

• Quick service restaurant (QSR) grill sheets and oven baskets

• Oven liners and baking sheets for domestic and professional use

• Processing and packaging of food items

Chemical Resistance

Resistance to chemicals is a key characteristic of Taconic’s PTFE coated glass fabrics. Harsh substances including acids and bases will attack and deteriorate most tapes, fabrics, and belts.

• Expansion joint and gasket materials

• Tray liners and conveyor belting

• Mold release tapes and fabrics

• Pipe wrapping