Heavy Weight Belting

Exceptional release properties, outstanding flexibility and superior temperature resistance.

Fabric Grades:

- Premium - These fabrics have a heavy coating of PTFE to provide the easiest release and the highest chemical resistance and electrical strength. Preffered for applications where fabric weave impression is undesirable and sticky materials are conveyed.

- Standard - Offering a smooth surface and excellent nonstick properties, this grade is the most widely used PTFE-Glass belt

- Mechanical & Economy - Light PTFE coating offers economy in applications where increased surface texture is useful.

- Crease & Tear Resistant - This grade offers substantially higher tear strength for high speed applications.

- Anti-Static/Conductive - Specially treated fabric reduces static build-up.

- Silicone Rubber Coated Fiberglass - These belts offer excellent release properties up to 500 F, superior abrasion, flex and chemical resistance and outstanding dielectric properties in demanding environments. Silicone belts are ideal in applications where high flexibility and a high slip coefficient are required. Available coated on one or two sides in red or white.

Applications

Click here to learn about the different applications for Taconic's heavy weight belts.

Heavy Weight Belting Products List:

| Description | Part Number | Nominal Thickness (inches) | Coated Weight (lbs/sq yd) | Tensile Strength Warp/Fill (Typical) (lbs/inch) | Tear Strength Warp/Fill (Typical) (lbf) | Maximum Continuous Operating Temp (F°/C°) |

|---|---|---|---|---|---|---|

| Heavy Weight Belting | ||||||

| Premium Smooth | 8039 | 0.009 | 0.28 | 75 / 70 | 3.25 / 2.5 | 500/260 |

| Premium Smooth | A952 | 0.0030 | 0.29 | 105 / 70 | 3.5/2.5 | 500/260 |

| Premium Smooth | TL-7300 | 0.0070 | 0.70 | 180 / 150 | 11.0 / 10.0 | 500/260 |

| Premium Smooth | 8109 | 0.01 | 1.0 | 300 / 175 | 10.0 / 8.0 | 500/260 |

| Premium Smooth | A1139 | 0.0105 | 1.00 | 290 / 180 | 11.0 / 6.0 | 500/260 |

| Premium Smooth | A1048 | 0.0245 | 2.16 | 565 / 545 | 18.0 / 17.0 | 500/260 |

| Premium Textured | 8279 | 0.026 | 2.04 | 475 / 575 | 25.0 / 15.0 | 500/260 |

| Standard Smooth | 8308 | 0.0028 | 0.26 | 95 / 70 | 3.25 / 2.5 | 500/260 |

| Standard Smooth | 8108 | 0.009 | 0.92 | 285 / 185 | 12.0 / 7.0 | 500/260 |

| Standard Smooth | 8148 | 0.0135 | 1.35 | 400 / 300 | 15.0 / 15.0 | 500/260 |

| Standard Textured | 8208 | 0.02 | 1.52 | 375 / 355 | 17.0 / 15.0 | 500/260 |

| Standard Textured | 8278 | 0.0255 | 1.8 | 425 / 500 | 25.0 / 20.0 | 500/260 |

| Economy Textured | 8226 | 0.0225 | 1.33 | 455 / 370 | 100.0 / 100.0 | 500/260 |

| Economy Textured | 8356 | 0.034 | 2.1 | 850 / 650 | 50.0 / 60.0 | 500/260 |

| Porous | 8115 | 0.013 | 0.77 | 250 / 215 | 25.0 / 15.0 | 500/260 |

| Crease & Tear Resistant Smooth | 8054 | 0.0047 | 0.45 | 160 / 160 | 6.5 / 5.5 | 500/260 |

| Crease & Tear Resistant Smooth | 8064 | 0.0055 | 0.5 | 175 / 150 | 9.0 / 7.5 | 500/260 |

| Crease & Tear Resistant, Textured | 8274 | 0.0245 | 1.74 | 450 / 625 | 60.0 / 80.0 | 500/260 |

| Tac-Black | 8103 | 0.0090 | 0.90 | 300 / 190 | 8.25 / 7.25 | 500/260 |

| Tac-Black | 8143 | 0.0148 | 1.36 | 410 /320 | 10.4 / 7.8 | 500/260 |

| Tac-Black Anti-Static | 8103-AS | 0.0095 | 0.9 | 280 / 210 | 8.5 / 8.0 | 500/260 |

| Tac-Black Anti-Static | 8143-AS | 0.0140 | 1.36 | 400 / 335 | 11.5 / 7.5 | 500/260 |

| Silicone Coated | 8242 | 0.0220 | 1.40 | 285 / N/A | N/A | 500/260 |

| Silicone Coated | 8231R | - | - | - | N/A | 500/260 |

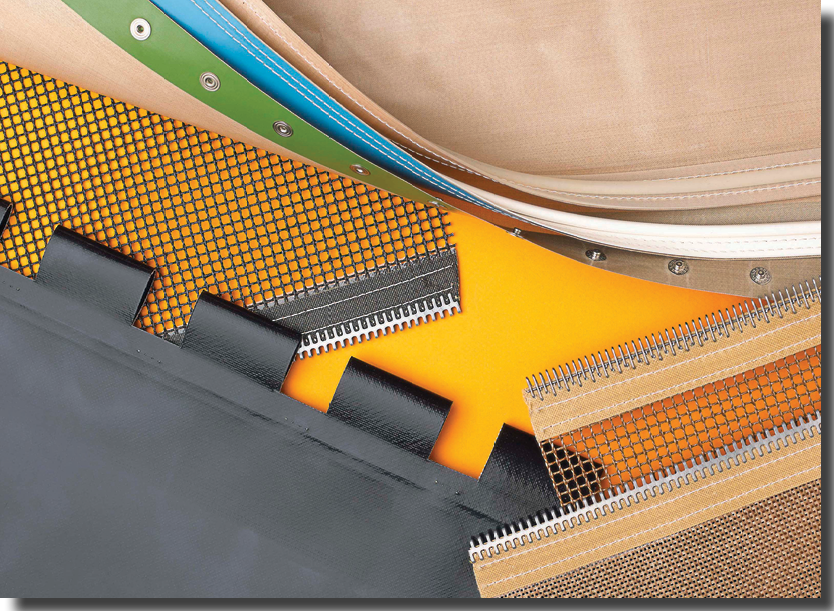

Fabrication Options

Click here to learn more about the types of splices, edge reinforcements and tracking & guiding devices we offer.

Ordering Your Taconic Belt

Please have the following information available:

- Dimensions of belt (width and length)

- Desired splice, edge reinforcement and tracking devices, where needed

- Pulley size and type

- Any special construction or instructions concerning belt fabrication. In cases of complex fabrication, a print may be requested