Shot Peening Masking Materials

Masking tape, fabric and compounds for Shot Peening

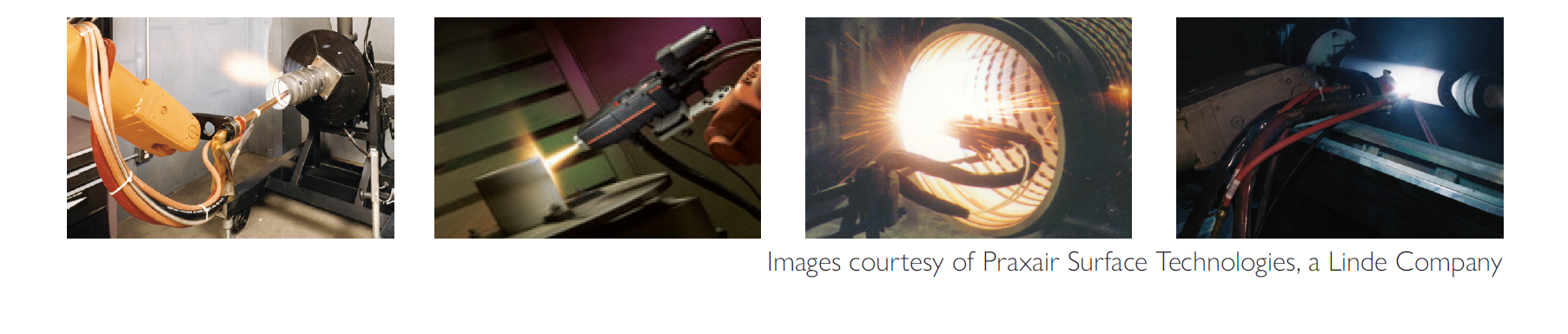

Shot Peening surface treatment is a process used to produce a compressive residual stress layer and modify the mechanical properties of metals. The process involves striking the substrate surface with shot (round metallic, glass or ceramic spheres) with force. The process is intended to strengthen and relieve stress in critical metal components. The main goal is to prevent the formation of micro-cracks.

Why is Masking Necessary?

Similar to grit blast and thermal spray coating, the stream of particles are targeted strategically. In the case of shot peening, it is important to protect areas that are not intended to be surface enhanced as unintended damage can be done. Shot peen masking requires material that can stay in place and act as a buffer/cushion to absorb the impact of the particles and protect the metal surface underneath.

Masking Options...Finding the Better Way

- Contamination Free Surface: Taconic thermal spray masking tapes, fabrics, and compounds are designed to leave no residual silicone adhesive nor fluid on the component surface.

- High Abrasion Resistance: Specific Taconic thermal spray masking materials are designed to withstand the high abrasion associated with the surface prep blasting and shot peening process.

- Flexibility & Conformability:Taconic thermal spray masking tapes, fabrics, and compounds are designed to conform to challenging profiles without lifting, sagging, or moving. These traits make Taconic materials idea for critical masking tasks.

- Peel Adhesion: Taconic pressure sensitive tapes offer industry leading adhesion to metal and face-to-back adhesion. The situation of tape lifting during coating can be catastrophic. For this reason, Taconic tapes are used to ensure the masking survives the coating process consistently.

- Impact Resistance: Specific Taconic tapes and compounds are designed to absorb the energy/impact of the shot peen particles thus protecting the desired surface area.

Finding a Better Way to Save Time & Money While Improving Masking Efficiency…

Use Strong Tape & Apply Fewer Layers of Tape – The stronger the masking tape, the fewer layers of tape that are required. Each layer of tape adds time and cost increasing the overall cost associated with a masking job. Using a strong tape allows you to mask in 1-2 layers which saves time and money.

Post Masking Properties – After the shot peening process is complete, the maskant must release as clean as possible. Removing adhesive residue, glass, and other unwanted potential contaminants adds extra time and cost to the entire process. Taconic masking materials are designed to remove completely clean from component surfaces.

What does the above mean for coating shops?

- Reduces time

- Reduces tape consumption

- Reduces overall spend

- Improves throughput

- Reduces clean up

- Eliminate Rework

Product Recommendations:

Taconic PSA Tapes:

- 6525-08: Abrasive resistant plasma spray masking tape. This tape is suitable for the most demanding plasma spray, flame spray, and electric arc spray applications where abrasion and heat are considerations.

- 6525-16: Double Layered Shot Peening masking tape. Double Layer allows for single layer application for each job. In cases where 2 layers of standard tapes are required, the 6525-20 can reduce masking times by up to 50%.

TacMold Masking Compounds:

- TacMold (A2023-A / A2023-B) masking compound is a 2 part silicone putty which is designed to withstand all forms of thermal spray including GF-HVOF and LF-HVOF. This putty is intended to assist with masking holes or complicated intricate profiles. In some cases, the compound is reusable.

- TacBloc - A soft, conformable, putty-like material for masking holes, grooves, key slots or any unique configuration. Unlike TacMold, TacBloc is formulated to adhere to metal in areas where anchorage is not possible. TacBloc is good for all forms of thermal spray.